Injection Molding

▌ Injection Molding

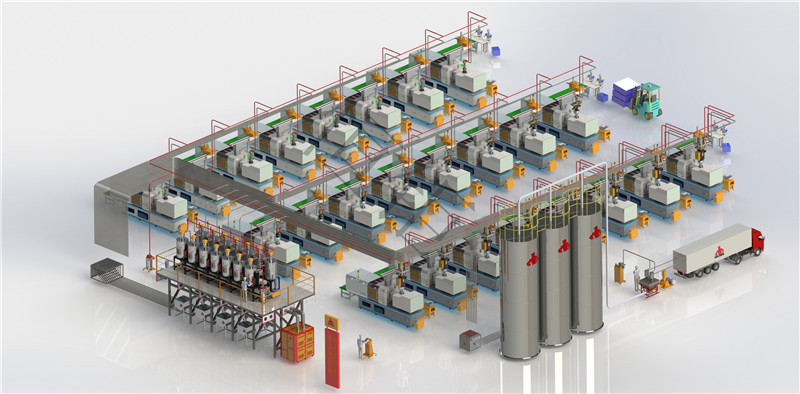

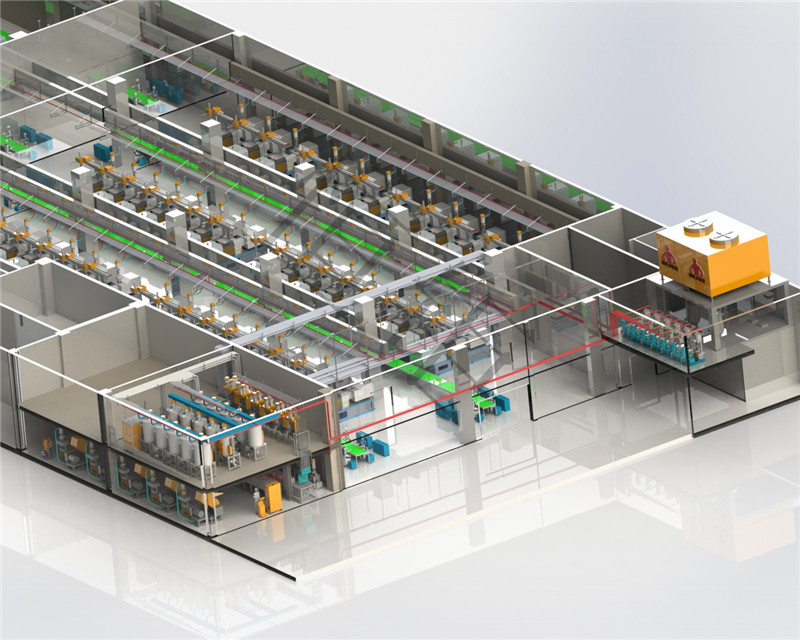

Injection molding workshop: why do you want to choose the central feeding system:

1, coloring process automation, blocking prevention: the central feeding system can realize continuous unmanned continuous molding operation, can according to need to change the raw materials in the process of operating varieties, a combination of color material usage, realize the automation of colouring process.And can be used in automatic way to regenerate and sprue cold material, to all the control of feeding equipment, and prevent the occurrence of surge bin in jams phenomenon, and improve the working efficiency of the injection molding workshop.

2, meet the requirements for product varieties: the central feeding system USES a microcomputer automatic control, to aggregate the 24 hours of continuous feeding operation, even in mixing, measuring accurate, flexible and can change the color, we can see that it adapt to multiple color product varieties in the injection workshop requirements.

3, safe and reliable work: according to the production of different molding machine, flexible change for shoes.Multiple feed pipeline design, can guarantee to injection workshop is main diversification requirements, at the same time have a variety of monitoring and protection function, safe and reliable work.

4, to adapt to any injection molding workshop equipment: the central feeding system can perform automatically to a variety of raw materials supply multicellular any kind of injection molding processing equipment, in which can include the raw material of color processing, dry processing, and according to the proportion of recycle material crushing, can implement high degree of automation control, monitoring, etc.

5, easy to operate, energy saving, the central feeding system operation simple, need only a handful of people that can control the whole injection molding plant feed demand, thereby reducing the large amounts of labor costs.Also reduced by the injection molding machine with raw material and the corresponding auxiliary equipment, improved the space utilization.In addition, with the central feeding way, corresponding to reduce a lot of single machine equipment, save electricity and reduce maintenance costs

▌ Injection Molding

Hengju is a professional manufacturer which dedicated to research develop and produce plastic processing auxiliary equipment, and meanwhile it’s a leading supplier for whole factory planning and design. Years of experiences in the plastic industry allows Hengju to take a lead in domestic industry, and has a great share in global markets. Our products has been supplied to over 20 countries around the world.Hengju always adheres to the company culture of people first. Our company provides the staff with relaxed working environment and comfortable accommodation, besides, a lot of professional training every year has helped our staff to improve. Everyone likes working here.Over years of development, Hengju always focus on quality and credibility and always provide our customers with good-quality products and excellent after-sale service which make us to keep our position as a global leader in our field.

Hengju is a professional manufacturer which dedicated to research develop and produce plastic processing auxiliary equipment, and meanwhile it’s a leading supplier for whole factory planning and design. Years of experiences in the plastic industry allows Hengju to take a lead in domestic industry, and has a great share in global markets. Our products has been supplied to over 20 countries around the world.Hengju always adheres to the company culture of people first. Our company provides the staff with relaxed working environment and comfortable accommodation, besides, a lot of professional training every year has helped our staff to improve. Everyone likes working here.Over years of development, Hengju always focus on quality and credibility and always provide our customers with good-quality products and excellent after-sale service which make us to keep our position as a global leader in our field.

CEO: Mr. Shaw

Mob: +86-18665848182

Tel.: +86-0757-87572602

Fax.:+86-0757-87572603

QQ:191113512

E-mail: HJ@gdhengju.com

Add.:NO.168, Xinjie Road, Dongcheng District, Dongguan, Guangdong, China

International Business Dept.

Sales Manager: Mr.Xiao

Whatsapp: 15817747776

Sales: Miss Peng

Whatsapp:15876905866

Engineer:Mr.Xiao

Whatsapp:18665848182

whatapp:

whatapp: