Extrusion &Blowing Moulding

▌ Extrusion &Blowing Moulding

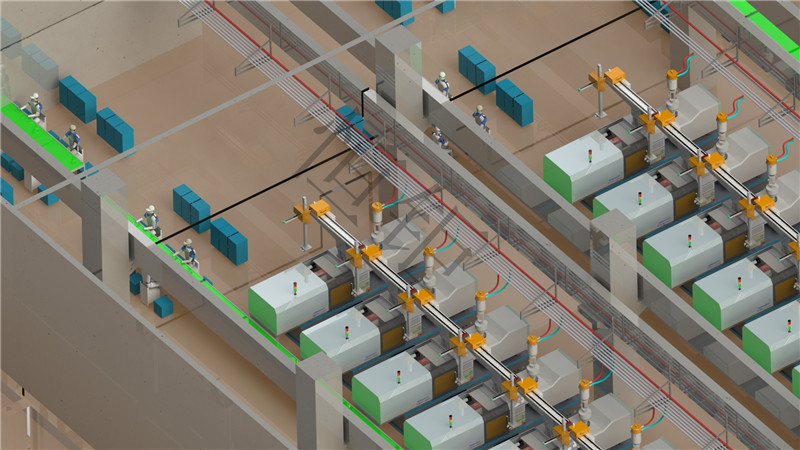

Blow molding process includes two main blow molding extrusion blow molding and injection moulding.Thermoplastic resin by extrusion or injection molding of plastic parison tube, hot (or heat to soften state) put in split cavity, mold closing immediately after ventilation with compressed air within the parison, make plastic parison swell and clingy wall in the mold, the cooling mold release, the products have all kinds of hollow.

Blow molding is used for thermoplastic materials in the production of hollow thin-walled a molding process, its typical products for the large capacity and the final consumer goods, such as bottles and containers.Current consumption is the biggest plastic varieties in the production of PE, PP, PVC.

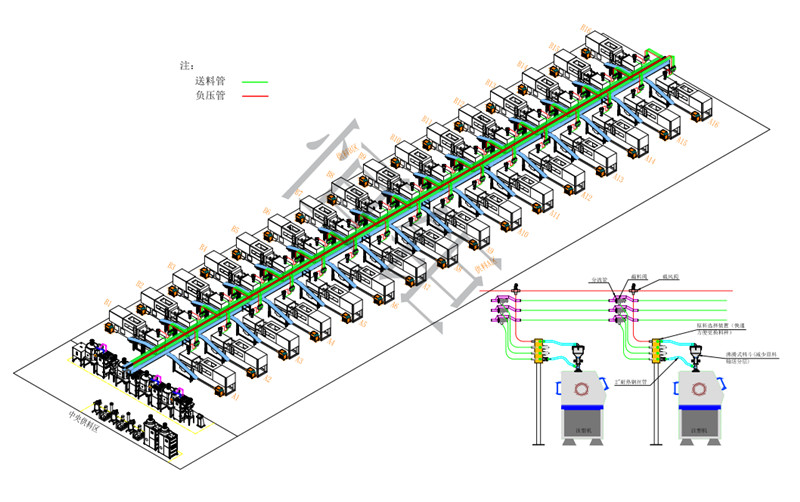

delivery

The number of blow molding machines can according to customer's workshop or put seat, put forward by central or stand-alone solutions.Contact with the raw material of parts adopt stainless steel material as well as the transmission system of filtering device, effectively ensure the raw materials in the process of transmission is not contaminated.

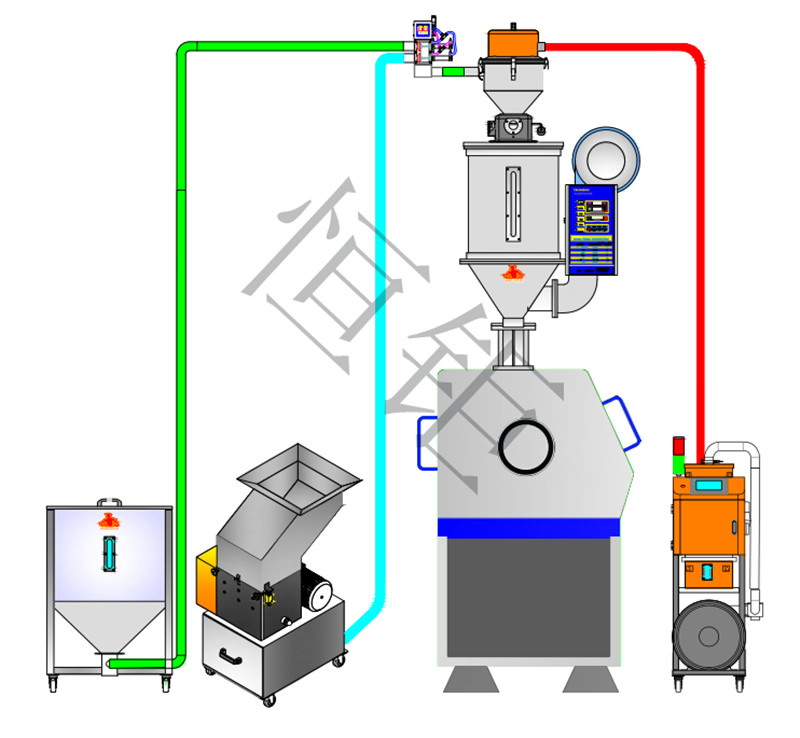

Absorption material

Cooperate with extrusion blow molding of absorb, constant major has multiple specifications suction machine, 300 g700g800g900g vacuum pump delivery for efficient, match with real-time detection filter differential pressure or vacuum protection device, in order to ensure timely cleaning and protection of vacuum pump.

Due to large extrusion blow molding raw material usage, consider vacuum the air volume of fan and pipe diameter, can satisfy each machine can sufficient use the raw material, also want to consider for the original distance transmission and easy to produce the raw material drawing.Suction feeder small volume, strong absorption material.

crushing

For the treatment of the poor, constant major crusher is suitable for crushing and recycling of various plastic products, such as bottles, plastic bottles, etc.The design of the centralized control, convenient manipulation;Close to the cutting room design of open mode, has high strength, good toughness and fracture characteristics of not easily, ensure good blade in the work, increase crushing grain quality and yield, and dismantling, repair, maintenance is very convenient.

Metering volume type pigment mixing machine

Constant major volume type machine tool can be used in the crystalline and non-crystalline material grain color color mother the measurement of raw material, production range of 0.2 ~ 32 kg/hr.If the customer add ratio and higher accuracy for masterbatch, we promote use gravity type color machine tool, using the measurement methods, production range of 0.04 ~ 32 kg/hr.

Internal cooling water circulation cooling function can prevent color masterbatch possible melt into the PET is main flow, thus ensuring the precise measurement.To set a number of mold cycle to add a masterbatch, trace measurement in order to meet the requirements.

Zero gravity type feeder

Zero gravity type feeder is to use a hunger packing way of raw materials added, by detecting the actual flow, automatic feeder adjustment screw speed, to achieve and maintain a set of feed rate.

Enclosed design, preventing environmental factors affect the machine use, is not easy to appear when used for powder add splash phenomenon.

Weighing type mixing materials mixing machine

In the crowded blowing process, the main raw material, the color masterbatch and recycle material by weighing type mixer, add in proportion.Constant major weighing type mixing materials mixing machine modular removable type structure design, save space and easy to clean;

The universal PLC controller to ensure reliable performance, convenient maintenance;

Ethernet interface, MODBUS, PROFIBUS communication module, which can realize remote monitoring, and compared with extrusion machines, injection molding machine, the host of data exchange.

Weightlessness hopper meter

Weightlessness hopper meter, it can press set production to control the speed of extruder screw extruder output in order to achieve a constant, hopper weight and related raw materials are made up of two eccentric sensors.Adopts the modular PLC technology, to ensure that the simple and practical operation.Control software including the weightlessness control, m \ production control, raw material consumption control.

Continuous gravity mixing machine

Continuous weightlessness measurement system, which is used to at the same time for multiple materials.Main ingredient by two eccentric the sensors, and then the data back to the control system, control system through other two eccentric sensor heavy on the raw material and adjust the speed of the screw with the main ingredient to achieve a constant ratio.

▌ ABOUT US

CEO: Mr. Shaw

Mob: +86-18665848182

Tel.: +86-0757-87572602

Fax.:+86-0757-87572603

QQ:191113512

E-mail: HJ@gdhengju.com

Add.:NO.168, Xinjie Road, Dongcheng District, Dongguan, Guangdong, China

International Business Dept.

Sales Manager: Mr.Xiao

Whatsapp: 15817747776

Sales: Miss Peng

Whatsapp:15876905866

Engineer:Mr.Xiao

Whatsapp:18665848182

whatapp:

whatapp: