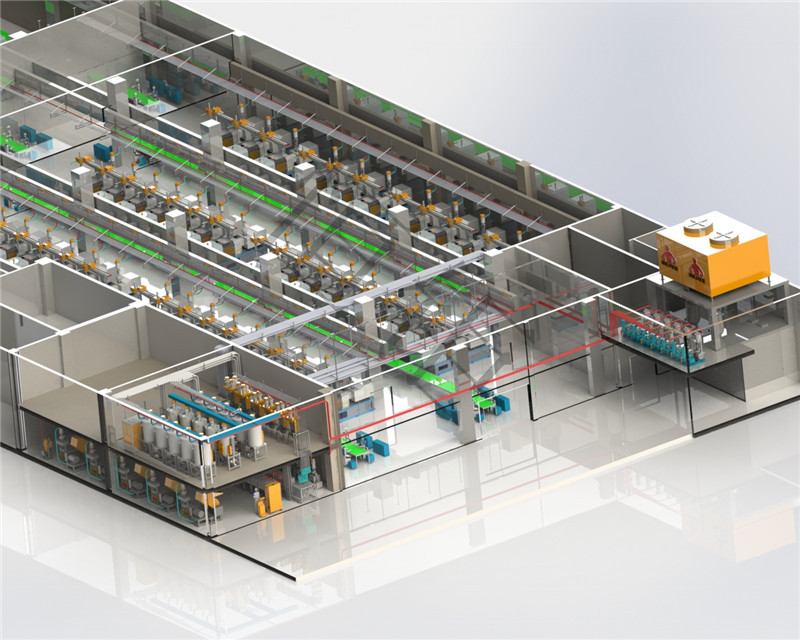

Centralized Conveying System

▌ Centralized Conveying System

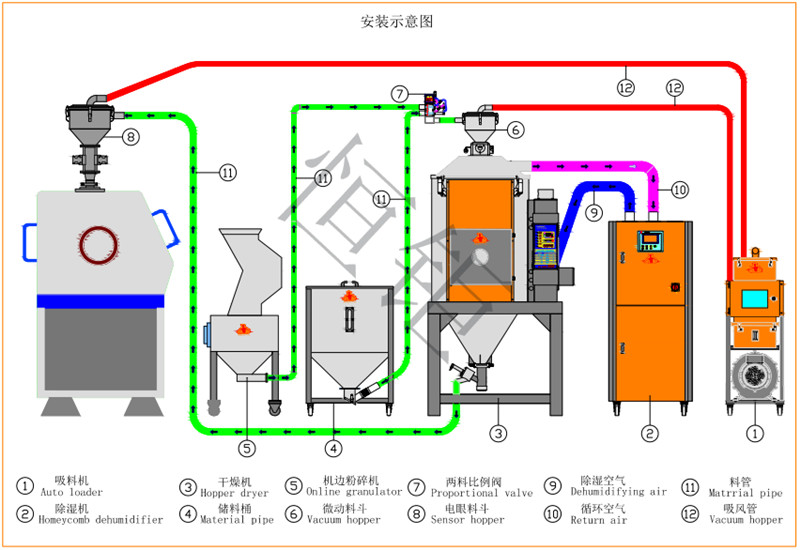

Constant major machinery can from the auxiliary equipment of plastic forming whole plant planning for you, including plastic raw material storage, the central feeding, drying to the measuring mixing, from the mold temperature control to the molding equipment cooling system, from automation manipulator to the shattering of the waste recycling, etc.

Storage and transportation

Regardless of small storage VAT or large outdoor storage bin, constant major all can provide you with the most appropriate central feed storage solutions, in order to save space for you, protect raw materials, to reduce the transportation cost.

Contact with the raw material of parts adopt stainless steel material as well as the transmission system of filtering device, effectively ensure the raw materials in the process of transmission is not contaminated.Flexible conveyor to fill the wind control system, by adjusting the transmission speed, effectively avoid the because of the different delivery conditions and make the raw material to produce wire drawing or the status of the dust.

For high temperature material conveying system, the constant major special design which has the function of water cooling solution, reduce the risk of a vacuum pump for conveying high temperature material.

Closed circulation of the two transmission system, constant major for hot materials and after drying should be sent to the machine on the insulation hopper conveying process, can greatly reduce because of conveying process of the dry heat loss and the risk of raw material moisture absorption again.

Distribution of raw materials

Standard manual material distribution station with fast connection, constant major differences stand allows you to select the best ingredients line, the central distributor and joint can improve the efficiency of the system.Automatic raw material distribution station USES the central control console, can be used in the large feeder system.

Measuring mixed

The SCM constant major volume type color machine tools can be used in pigment raw material measurement, production range of 0.2 ~ 32 kg/hr.If the customer for pigment adding ratio and higher accuracy requirement, we recommend weightlessness SGD type color machine tools, adopts weightlessness measurement method, production range of 0.04 ~ 32 kg/hr.

One kind of main ingredient of plastic materials and 1-4 kinds of color masterbatch or additive automatic mixed in proportion, suitable for injection molding, extrusion or blow molding production.

Weighing type mixing materials mixing machine

Ethernet interface, MODBUS, PROFIBUS communication module, which can realize remote monitoring, and compared with extrusion machines, injection molding machine, the host of data exchange.(e.g., maximum output and actual output, the matching accuracy) controller standard USB2.0 interface, the mixture ratio of data can be saved to a usb drive, convenient for production quality control.With sound and light alarm, facilitate equipment operators fast accurate fault machine field, all parts in contact with the raw material made of stainless steel materials, to prevent contaminated materials.

Dehumidification drying

In the plastic molding process, dry become are particularly crucial phase, must ensure that the moisture content in the raw material is removed and the drying temperature is reasonable.Greatly improve the quality of products, low power consumption, high efficiency, stable supply - ~ 30 ℃ and 40 ℃ the dehumidification air dew point.

Propeller honeycomb dehumidifier main parts adopt imported components, carefully select material, good workmen assembled.Is the main purpose of the machine and hot air type hopper dryer is tie-in, the hygroscopicity strong engineering plastics (such as: PA, PC, PBT, PET, etc.), high efficiency of dehumidification drying operations.

Out of control

Cooling air ring and film thickness gauge

For plastic film blowing machine, wind ring is one of the important components membrane bubble forming, cooling, the wind ring of film thickness uniformity and film production has a great impact.

Weightlessness hopper meter

Is a gravity type hopper meter, it can be set according to the production to control the speed of extruder screw extruder output in order to achieve a constant, hopper weight and related raw materials are made up of two eccentric sensors.Adopts the modular PLC technology, to ensure that the simple and practical operation.Control software including the weightlessness control, m \ production control, raw material consumption control.

Continuous gravity mixing machine

Continuous weightlessness measurement system, which is used to at the same time for multiple materials.Main ingredient by two eccentric the sensors, and then the data back to the control system, control system through other two eccentric sensor heavy on the raw material and adjust the speed of the screw with the main ingredient to achieve a constant ratio.Control software including the weightlessness control, m \ production control, raw material consumption control.

▌ ABOUT US

Dongguan heng major mechanical equipment co., LTD. Is a professional manufacturer of plastic surrounding ancillary equipment manufacturers; We can provide customers with plastic molding workshop to provide whole plant design; Rough grains from the workshop to raw material storage and raw material ratio measurement, crushing the recycling - dehumidification drying - to machine the application and management of real modern workshop.

Concentrated feeder system contains the whole factory water, electricity, gas automatic feeding system; Single machine equipment: slow grinder, medium speed mill, crusher, desiccant dryer, in1 dehumidifier, plastic auxiliary machinery, plastic drying machine, crystal machine, suction machine, drying machine, mixer, stainless steel sieve machine, die temperature machine, cold water machine, weighing type mixer, volume type meter;

Welcome new and old customers to plant counseling and guidance, more the central feeding system login details: www.gdhengju.com

CEO: Mr. Shaw

Mob: +86-18665848182

Tel.: +86-0757-87572602

Fax.:+86-0757-87572603

QQ:191113512

E-mail: HJ@gdhengju.com

Add.:NO.168, Xinjie Road, Dongcheng District, Dongguan, Guangdong, China

International Business Dept.

Sales Manager: Mr.Xiao

Whatsapp: 15817747776

Sales: Miss Peng

Whatsapp:15876905866

Engineer:Mr.Xiao

Whatsapp:18665848182

whatapp:

whatapp: