Optical & Medical Solutions

▌ Optical & Medical Solutions

In recent years, the plastic application in the field of health care for the other traditional materials can realize product innovation, continuous rising medical costs, forcing people to take the products to reduce costs, so that the disposable medical plastics products are increasingly replaced can be sterilized glass products, more health, and is very convenient, medical plastic products widely used in medical field.

The solution:

delivery

In the process of raw material conveying, can give plastic pollution pose a potential threat only air conveying equipment and contact with the plastic.Constant major offered by the medical optical process of raw material conveying equipment adopt food-grade stainless steel materials, and the air system for efficient filter, makes the air into the system meets the requirement of clean room.

Pipeline by SUS304 stainless steel or glass manufacturing, special pipe connector really realize the seamless connection;Soft pipe using food grade PU tube and wire connection, to ensure to eliminate static electricity;Use HEPA high efficiency air filter, filtration precision is 0.3 (including m, filtering efficiency up to 99.995%.

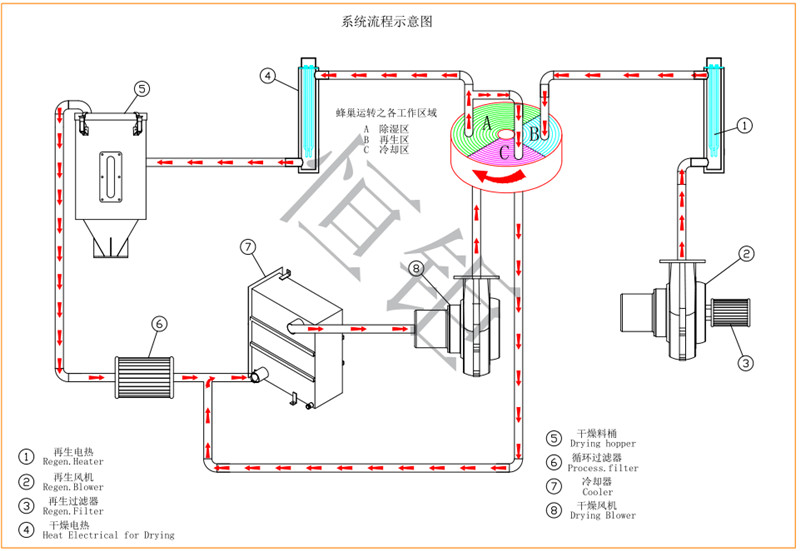

dry

Dry wind circuit is equipped with high efficiency dust separator, can fully guarantee the dry air filter;Drying system internal standard HEPA efficient filter, which can effectively filter dust ion of 0.3 mu m, filtration rate was 99.995%;All raw material contact surface polishing treatment adopts stainless steel SUS304, and loop closed feeding system collocation, can avoid the pollution of raw materials or return.

storage

Made of stainless steel SUS304 internal polishing processing, do not pollute the raw material;Closed structure design, make the raw material is not affected by outside air pollution;Discharging mouth special wind device, can smoothly to achieve more raw material conveying;When customers don't match HEPA filters when using of high performance, to provide a filtering accuracy for simple filters using 5 microns.

Mold temperature

Permanent mold temperature machine, various kinds of major development, water type mold temperature machine, die temperature machine, oil type high temperature and mold temperature machine, specular steam mold temperature machine, double temperature one die temperature machine, equipped with turbine pump, flow pump, magnetic drive pumps and microcomputer controller, can meet all requirements of different raw material processing field.

The P.I.D control temperature system, can maintain stability under any operating state mold temperature, temperature control precision can reach + / - 0.1 ℃;Efficiency of heat pump, can be applicable to precision mold and small diameter mould of temperature control requirements of circuit, to realize precision control moderate high efficiency heat exchange;LCD screen display the measured temperature and set temperature directly.

cooling

Constant major chiller cooling system can achieve precise control of temperature, flow rate and pressure, the maximum refrigerating effect, its products include air cooled and water cooled chillers, cooling towers, pump and water tank.Based on the standard equipment technology, on the basis of constant major to meet the different needs of customers personalized solutions.

Water/air cooled in ice water machine, open the cold water machine, a new combination, well-known brand compressor and evaporator super cooling, quiet save electricity.There is single, double, four units, high energy efficiency.

Constant major volume type machine tool can be used in the crystalline and non-crystalline material grain color color mother the measurement of raw material, production range of 0.2 ~ 32 kg/hr.If the customer add ratio and higher accuracy for masterbatch, we promote use gravity type color machine tool, using the measurement methods, production range of 0.04 ~ 32 kg/hr.

Internal cooling water circulation cooling function can prevent color masterbatch possible melt into the PET is main flow, thus ensuring the precise measurement.To set a number of mold cycle to add a masterbatch, trace measurement in order to meet the requirements.

Weighing type mixing materials mixing machine

Special high temperature type weighing type mixing materials mixing machine is designed, including the weighing sensor and material level detector, can deal with PET crystallization of high temperature materials processing.

Controller with Ethernet interface, with the corresponding software can be through the communication interface read raw material proportioning data (e.g., maximum output and actual output, the matching accuracy) in order to control product quality.

Color graphic displays, touch screen operation, have formula storage function, can store up to more than 100 recipes, the use of advanced control algorithm, independent optimization, PLC controller, reliable performance, easy maintenance.

▌ ABOUT US

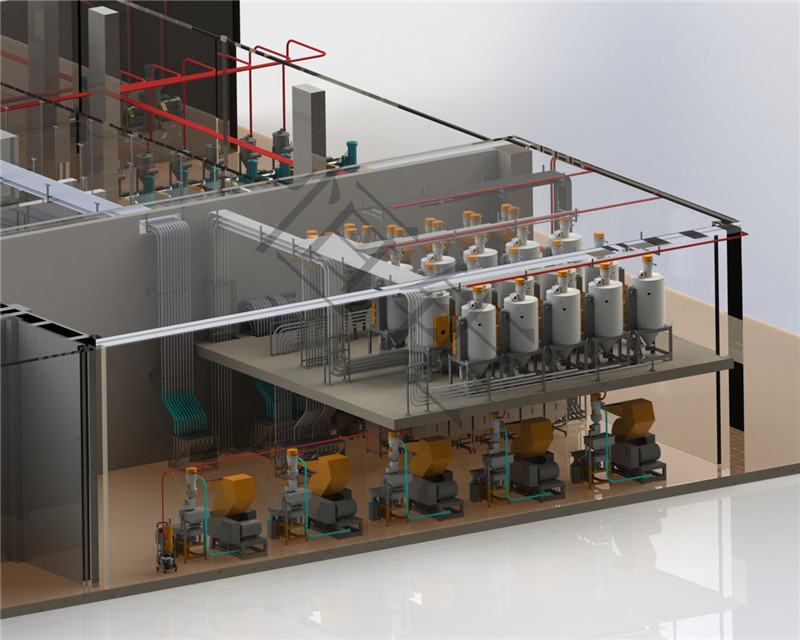

Hengju is a professional manufacturer which dedicated to research develop and produce plastic processing auxiliary equipment, and meanwhile it’s a leading supplier for whole factory planning and design. Years of experiences in the plastic industry allows Hengju to take a lead in domestic industry, and has a great share in global markets. Our products has been supplied to over 20 countries around the world.Hengju always adheres to the company culture of people first. Our company provides the staff with relaxed working environment and comfortable accommodation, besides, a lot of professional training every year has helped our staff to improve. Everyone likes working here.Over years of development, Hengju always focus on quality and credibility and always provide our customers with good-quality products and excellent after-sale service which make us to keep our position as a global leader in our field.

Hengju is a professional manufacturer which dedicated to research develop and produce plastic processing auxiliary equipment, and meanwhile it’s a leading supplier for whole factory planning and design. Years of experiences in the plastic industry allows Hengju to take a lead in domestic industry, and has a great share in global markets. Our products has been supplied to over 20 countries around the world.Hengju always adheres to the company culture of people first. Our company provides the staff with relaxed working environment and comfortable accommodation, besides, a lot of professional training every year has helped our staff to improve. Everyone likes working here.Over years of development, Hengju always focus on quality and credibility and always provide our customers with good-quality products and excellent after-sale service which make us to keep our position as a global leader in our field.

CEO: Mr. Shaw

Mob: +86-18665848182

Tel.: +86-0757-87572602

Fax.:+86-0757-87572603

QQ:191113512

E-mail: HJ@gdhengju.com

Add.:NO.168, Xinjie Road, Dongcheng District, Dongguan, Guangdong, China

International Business Dept.

Sales Manager: Mr.Xiao

Whatsapp: 15817747776

Sales: Miss Peng

Whatsapp:15876905866

Engineer:Mr.Xiao

Whatsapp:18665848182

whatapp:

whatapp: